5MAY

5MAY

Start of the Green SmartFactory 4.0 project

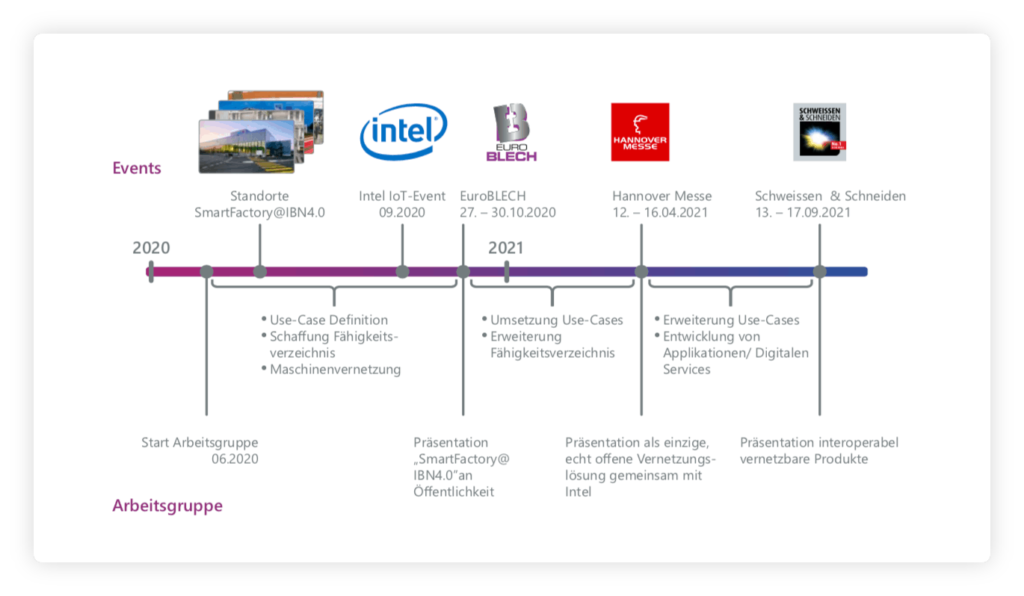

From June 2020, the first participants of the Green SmartFactory 4.0 project will start - the common goal: to network assets with the cross-manufacturer networking solution IndustryFusion and, on this basis, to create interoperable Industry 4.0 products by the Schweissen & Schneiden trade fair in 2021.

The working groups of the Green SmartFactory 4.0 project are the starting signal for the concrete networking with IndustryFusion - the open source project of the Industry Business Network 4.0 e.V. for the cross-manufacturer networking of different assets (machines, components, applications ...) in a Smart Factory. Together with the partners Intel, 1&1 Ionos, Iteratec, codecentric, Thomas-Krenn.AG, 5eEcosystems and DECENT, IndustryFusion has created a future-proof, scalable open-source reference architecture that is independent of any particular IoT platform provider and can be freely used for the implementation of commercial products.

In the project's working groups, each participant is now given the opportunity and the tools to integrate their assets, implement Industrie 4.0 use cases and build new digital customer solutions. On an ongoing basis, the participants present their results at "SmartFactory@IBN4.0", the association's new, cross-location digital demo factory. In concrete terms, this means that regardless of the location of the respective assets, they can be integrated into SmartFactory@IBN4.0 across manufacturers and are networked with each other - the aim is to make all connected showrooms/assets with different use cases transparent and visible 24/7.

All this with the overriding goal of bringing interoperable Industrie 4.0 products and solutions to market by the Schweißen&Schneiden 2021 trade fair at the latest. The participants are supported by implementation partners from the software and hardware sector such as Intel, Iteratec, codecentric, Thomas Krenn and 1&1 Ionos. They contribute their expertise to accelerate the development and to bring the innovations quickly to the market.

Would you also like to network your assets across manufacturers

and build new digital customer solutions?

What will be specifically developed by whom within the framework of the working group?

Semantics area

Tasks working group

- Definition of which data should be transferred from specific machine category

- " Result: Textual description of the capability inventory

Tasks machine manufacturer

- Provision of the necessary data to the control interface (if necessary, addition of the necessary sensors in the machine and integration into the control programming).

- " Result: Machines prepared according to the version of the capability list

Tasks Implementation partner

- Implementation of new versions of the capability directory

- Update of the asset driver per machine

- " Result: Implemented capability directory and assets connected

Area machine connection / networking

Tasks working group

- Control interface adaptation guide for machine manufacturers

Tasks machine manufacturer

- Selection of the machine type

- Adaptation of the machine control / creation interface

- Physical networking of the machine on site (e.g. showroom)

Tasks Implementation partner

- Machine gateway / SmartBox

- Implementation of the capability directory (v0.1) and the asset driver

- Connection to cloud for display of the "SmartFactory@IBN4.0".

- Creation Access to the dashboard of the "SmartFactory@IBN4.0" with all involved assets, stürmsfs as well as the test and competence centers

Use cases area

Tasks Working Group:

- Definition and description of the use cases

- Derivation of the user stories/features to be implemented

- " Result: Textual description of the use cases and user stories (features)

Tasks machine manufacturer:

- Extension of the machine, control programming and interface for the implementation of the use case

- " Result: Machines prepared for use case

Tasks Implementation Partners:

- Breaking down user stories into SW features

- Implementation of the SW features

- " Result: Implemented features for use case

Marketing area

Joint marketing of the working group members:

- Connected to IndustryFusion" machine logo for each asset

- Social media posts and press releases

- Events

- " Result: Public presentation of the results of the "SmartFactory@IBN4.0".

Roadmap 2020/21

What does participation in the project entail?

- Project organization and management

- Overall project management, planning and coordination of project deliverables, milestones, deadlines and resources, creation of working groups and tracking of tasks, involvement and coordination of implementation partners.

- Access to documents and participation in definition/standardization of capability directories.

- Participation in the definition of requirements for the further development of the open source software IndustryFusion, contribution to the implementation of the features

- Access and visibility in the "SmartFactory@IBN4.0"

- Advice and explanation of terms related to Industrie 4.0 (digital twin, RAMI 4.0, ...) in general

- Consulting implementation machine adaptation regarding industry 4.0

- Consulting Promotion of research & development

- Definition of use cases and derivation of applications/digital services in corresponding subprojects (e.g. SmartFiltering, Production Sharing, ...)

- Updates & upgrades during the project " All members benefit from new features of the open source project

- Marketing & Advertising

You find this approach interesting and would like to join?